- Menu

-

About Us

Gansu Hongfeng Machinery Co., Ltd. is located in Pingliang City, Gansu Province, an important town in the center of the ancient Silk Road and Shaanxi, Gansu and Ningxia, and is a high-tech enterprise restructured and reorganized by the state-owned 920 Factory, a large-scale second-class military enterprise, and a backbone enterprise of strategic emerging industries in Gansu Province.

-

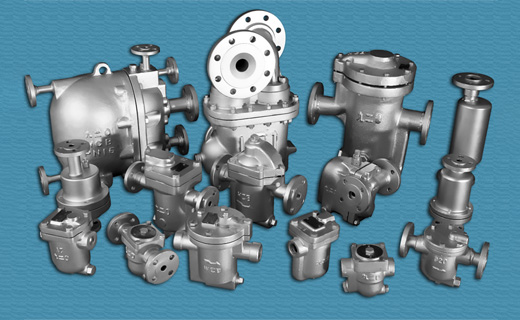

- Chinese Standard Steam Trap

- American Standard Steam trap

- Air Trap / Gas Trap

- Condensate Recovery Unit

- Exhaust Steam Recovery Unit

- Integrated Heat Trace Station / Trap Station

- Pilot-Operated Reducing Valve

- Temperature and pressure reduction device

- Pipe Fittings

- Temperature and pressure reduction device

-

Service

In the course of specializing in the production of energy-saving products and energy-saving devices such as traps and condensate recovery devices, "Hongfeng" takes the revitalization of the national equipment manufacturing industry and the creation of a national brand of traps as its own responsibility, closely tracks the development trends of science and technology and production trends, adheres to the technological innovation strategy of "no one has me, no one has me, no one has me, and I am new", and has realized the transformation from technology introduction, reference and absorption to independent innovation and independent development.

-

Quality

Based on the strict requirements of the steam system for the reliability, stability, durability and safety of pump and valve equipment, the company has established a complete set of quality assurance and control systems including procurement management, production control, performance verification, quality inspection, after-sales service, etc., and wholeheartedly escorts high-quality products.

-

News

We always respect and love our customers, and regard them as friends and siblings, and dedicate perfect services with a grateful heart, because customers are the pillar and source of our career success.

- 中文網(wǎng)站